Laminate and melamine are common finish surfaces for many countertops cabinets and shelves but these plastic materials are known for being susceptible to wear not to mention becoming quickly outdated.

High density phenolic laminate with a bonded melamine surface.

17 3 8 x 3 1 4 x 3 8 added on november 10 2019 more information.

Particle board is often confused with oriented strand board also known as flakeboard waferboard or chipboard a different type of fiberboard that uses machined wood flakes and offers more strength.

Made from high density phenolic laminate with a bonded melamine surface.

Particle board also known as chipboard is an engineered wood product manufactured from wood chips or jute stick chips and a synthetic resin or other suitable binder which is pressed and extruded.

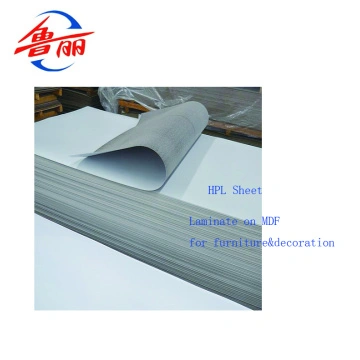

Hpl or high pressure laminate.

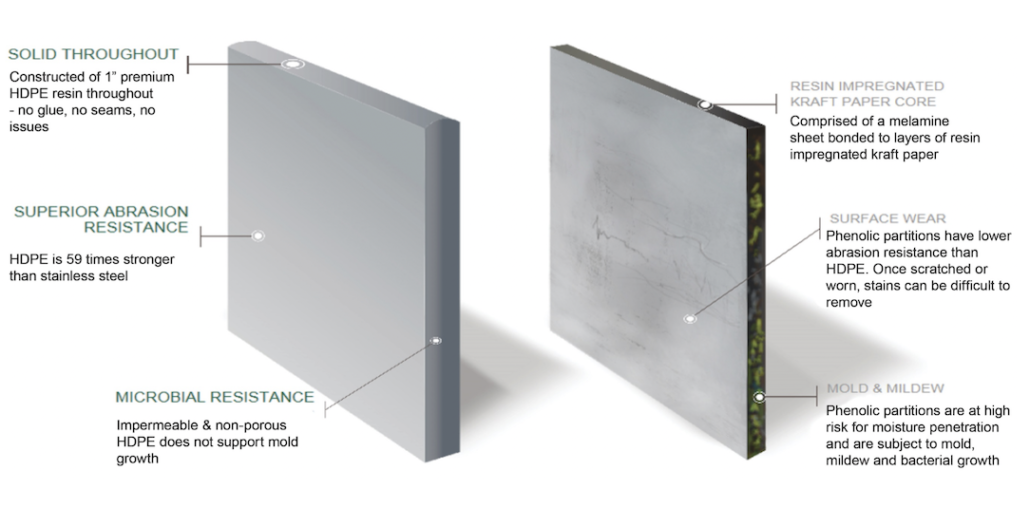

They offer superior rigidity flatness durability and low friction.

User friendly features include top accessible leveling screws lateral adjustment screws for a vibration free fit rear anti lift pin except jt 1 and a precut blade bottom.

Applications include bench tops joinery wall panelling lockers tables where scuff resistance is prominent.

Find additional warranty information.

They tend to get scratched and nicked with normal use and many countertops have a burn mark or two.

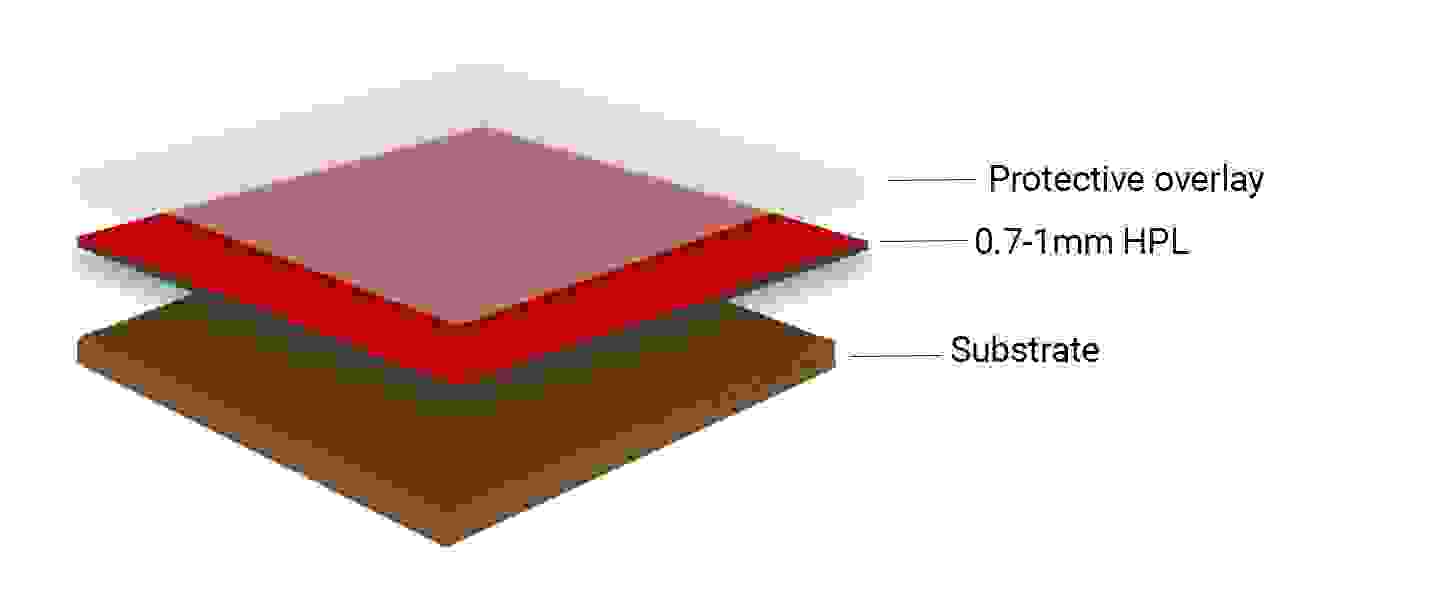

Made up of a wear resistant overlay decorative sheet and impact resistant kraft wilsonart high pressure laminate hpl offers long lasting beauty function and performance.

On vertical surfaces it is commonly used for doors and drawer fronts of cabinets.

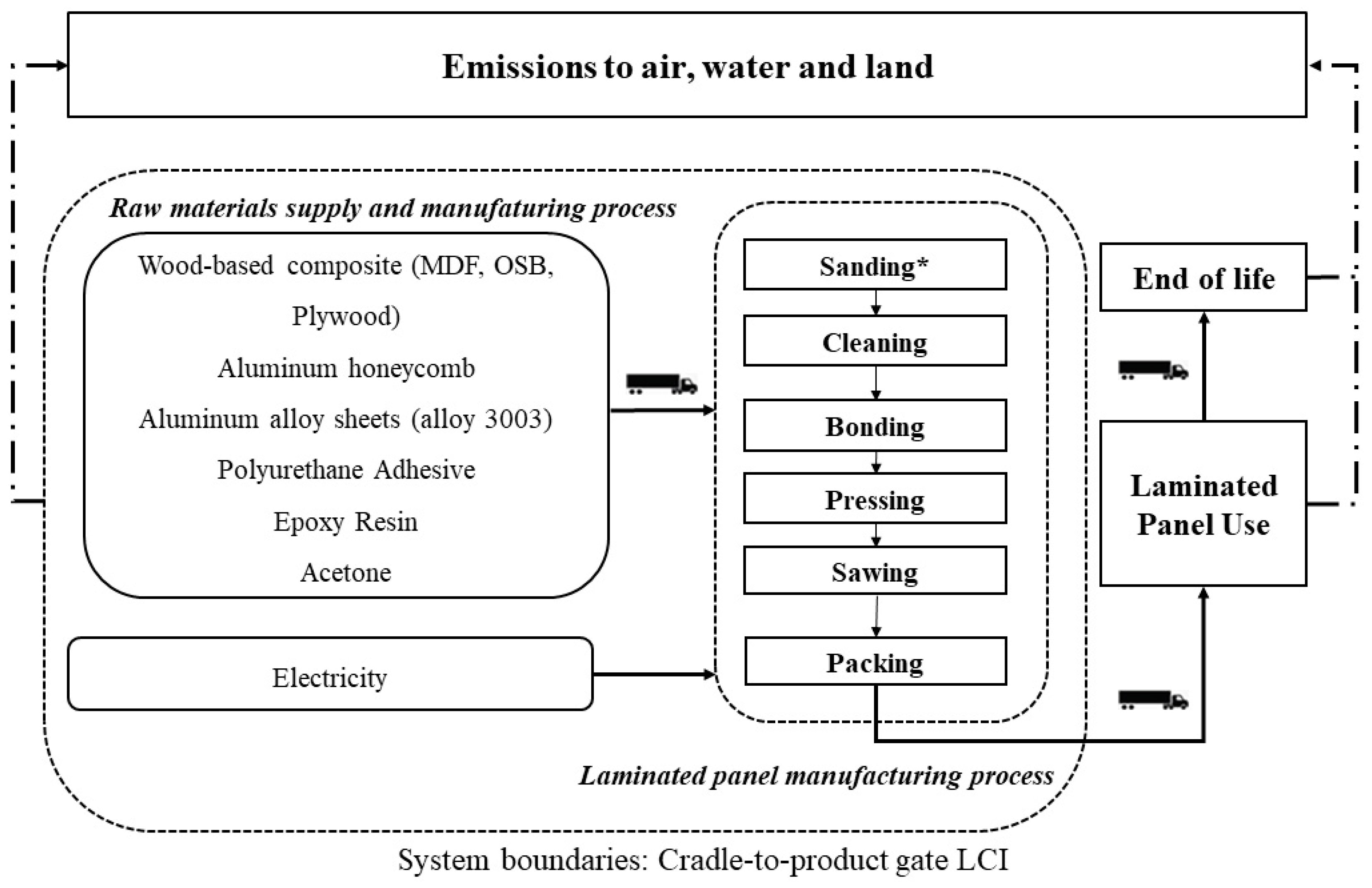

It is made of several sheets of paper that get bonded together using high pressure presses.

A high performing durable engineered surface used for a variety of vertical and horizontal applications wilsonart s hpl also offers a broad range of attractive patterns and texture possibilities.

It is used in many horizontal applications such as counter tops and higher quality table tops.

Hpl is about the most durable laminate available.

Melamine high pressure laminate is commonly referred to as hpl and is manufactured under 1000kg per square metre of pressure pressing down on 6 to 8 layers of kraft paper bonded with phenolic resin glue then topped by a polymer facing.

17 3 8 x 3 1 4 x 3 8.