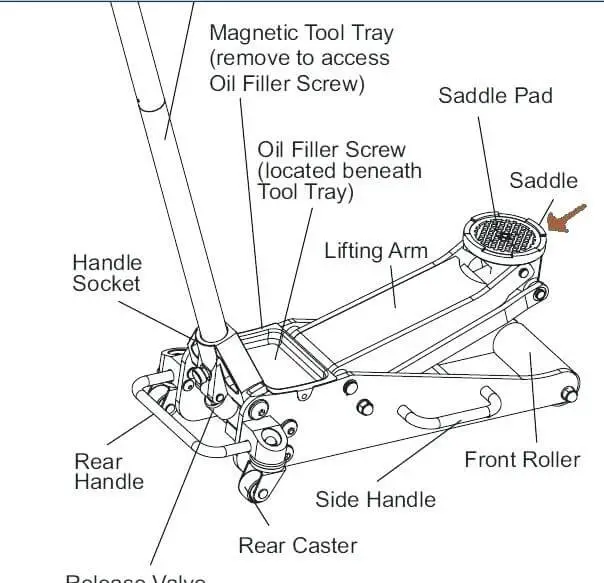

Open the reservoir cap and fill it with hydraulic oil until it is about 1 4 inch below the level of the hole when the jack is on its side.

How to fix a hydraulic floor jack reservoir.

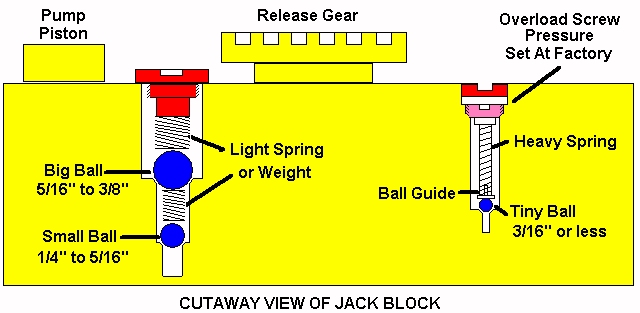

If any type of debris or dirt gets into the hydraulic fluid it can do a lot of damage to the inside of the cylinders.

Depending on the make and model of the jack some can hold up to a pint of fluid.

After which turn the jack s release position and pump it a few times to purge the accumulated air out.

Anytime you are going to be working on or maintaining your hydraulic floor jack it must be clean before starting.

Hydraulic fluid would be best but oil can be used temporarily.

Wipe off excess oil then test it.

If the level is higher than the recommended level then you will need to drain some of it.

Make sure that you use the best hydraulic oil and not some cheaper alternative.

Fill the chamber with hydraulic fluid.

Step 2 remove any excess air from the jack by opening the release valve and vigorously pumping the handle.

When this occurs the air starts to accumulate in the unit preventing it to lift.

In this video i show you how to fix a few common problems with your hydraulic floor jack.

They are easy to repair and it can save you 150 200.

For detailed instructions on how to change hydraulic oil for both floor and bottle jacks please refer to this video.

A substitute for hydraulic fluid is 5w 30 motor oil.

Use the funnel to guide the fluid into the cylinder.

If the level of oil in the floor jack is lesser than the recommended level then you can refill it.

Use shop rags to wipe down the cylinders thoroughly before you open any.

Refill the reservoir until it s full then place the seal cap back.

Hydraulic jack how it works animation a hydraulic jack uses a liquid which is incompressible that is forced into a cylinder by a pump plunger.